Knowledge Encyclopedia of Ceramic Body Reinforcer

At present, in the production of wall and floor tiles, there is a widespread phenomenon of poor green body strength, which leads to more damage to semi-finished products, especially porcelain tiles. Due to the large number of barren materials in the formulation, the problem of poor green body strength is particularly prominent. Because of the poor strength of the green body, during the process from press forming to firing in the kiln, the green body is easily damaged due to factors such as vibration, collision and mechanical pressure during printing caused by mechanical transmission or manual handling, and sometimes the damage rate even exceeds 20%, resulting in product degradation, seriously affecting the improvement of production efficiency and product quality. (Foshan Goway body enhancer FG-253 product does not affect the flow rate of mud, eliminates black cores and reduces rotten bricks)

Therefore, this problem must be solved. One way to solve this problem is to increase the forming pressure of the press. However, when the press pressure is increased to a certain level, the effect of increasing the strength of the green body is not obvious, but it is easy to cause forming defects (such as interlayer) And with the increase of repulsion, the cost and energy consumption of forming equipment also increase.

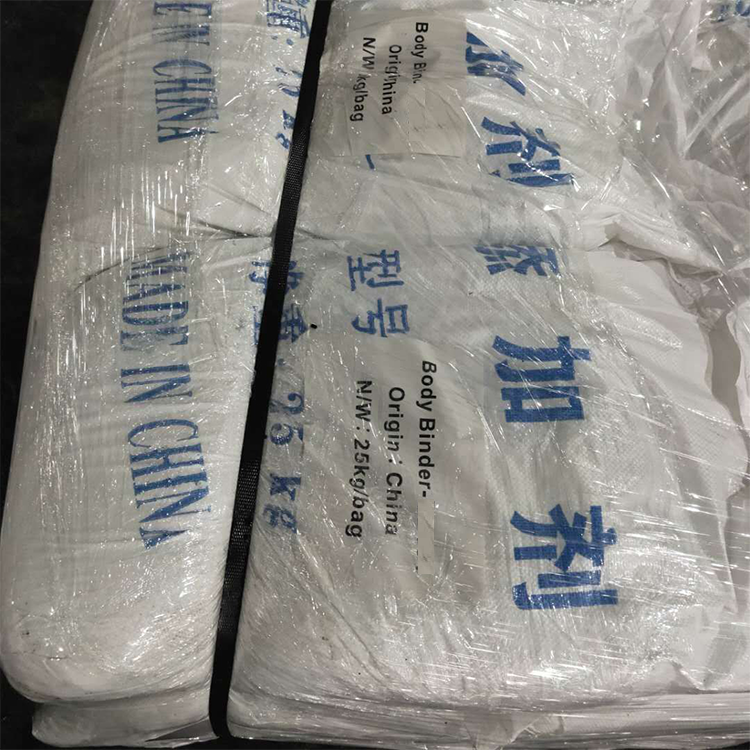

The method to increase the strength of the green body is to add an appropriate amount of reinforcing agent, which is usually composed of polymer organic compounds. When the sintering temperature reaches 400-500 °C, most of the organic reinforcing agent is carbonized and lost. The resulting porcelain blank has no effect. When in use, the green body strengthening agent is usually added to the slurry and mixed uniformly, the addition amount is 0.15% to 0.3%, and then spray-dried and granulated. Using this powder to make the green body, the green strength can usually be increased by 20% to 50 %.

For example, when a domestic factory presses 300mm×300mm porcelain tiles, it uses a green body intensifier. When the added amount is 0.3%, the green strength is increased from the original 0.98MPa to 1.43MPa (using 1000t automatic Hydraulic press), higher than the green body strength (1.22MPa) of a 1500t press when no strengthening agent is used. Some countries require the green strength of porcelain tiles to exceed 2.2MPa. There are two types of green body enhancers: powder and liquid. The former is easy to pack and transport but is easy to absorb moisture and agglomerate, while the latter is easy to disperse evenly in the ceramic slurry, which is more convenient to use and can stabilize the slurry. , Even if the added amount is as high as 5%, it will not thicken the slurry and will not affect the fluidity of the slurry.

The above content is selected from "Ceramic Additive Application Technology" by Yu Kangtai

The methods and precautions for using green body reinforcement in the production of wall and floor tiles are as follows.

(1) The added amount of Goway liquid enhancer is usually 0.15% to 3% (relative to the ball mill dry material).

(2) Goway enhancer can be added to the ball-milled slurry and stirred for more than one hour to achieve uniform mixing, or after the slurry is ball-milled, add the enhancer to re-grind and then release the slurry. Be careful not to mix the enhancer with The slurry is ball milled together for a long time (not more than 4h), otherwise the bonding strength will be reduced due to the destruction of the long organic polymer chain.

(3) When spray drying the slurry, the moisture content of the powder should be controlled at 5% to 7%. If the moisture content of the powder is too high, it will easily cause interlayer and sticking during forming.

(4) The influence of molecular weight and holding time on the strength of the green body should also be considered.

Keyword:

More News

Ceramic Deflocculant Guide: How to Choose the Right One for Your Slip

2026-01-22

The Bio-Stability Protocol: Eliminating Bacterial Degradation in Ceramic Slurries

2026-01-16

The Non-Stick Protocol: Eliminating Demolding Adhesion in High-Volume Casting

2026-01-14

Industrial Winterization Protocol: Mitigating Deflocculant Freeze-Thaw Instability

2026-01-12

The CMC Biostability Protocol: Eliminating Bacterial Degradation in Industrial Glaze Systems

2026-01-10

The Sodium Attack Protocol: Mitigating "Soft Shell" Defects and Mold Erosion in Mass Production

2026-01-08