Goway tells you the practical application of ceramic debonding agent

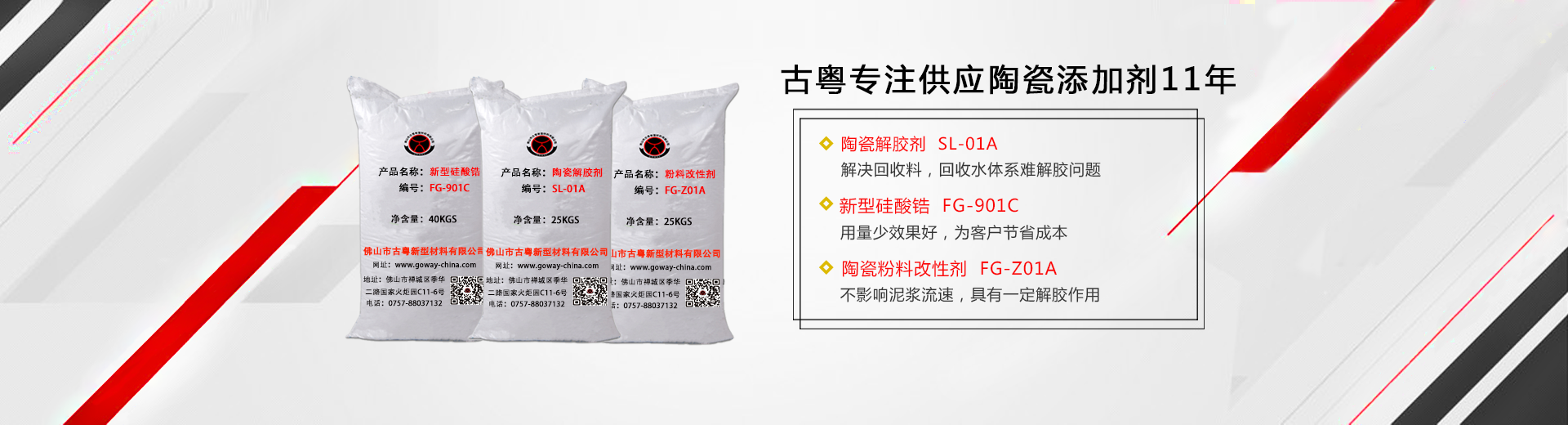

Ceramic debonding agent is widely used in the process of mud making, refining and glaze making in the ceramic industry. It can make the mud and glaze have low water content, good fluidity, non-returning and good stability. Once the products of Goway were put on the market, they were warmly welcomed by the ceramic enterprises.

Goway's glue-relieving agent can completely or partially replace STPP with lower cost. It has a wide range of debonding, and it has a better effect on high-aluminum, recycled materials and other difficult-to-dissolve formula system muds. Effectively debond the ceramic blanks, thereby reducing the viscosity of the slurry, improving the fluidity, reducing the moisture, saving the energy consumption of ball milling and drying, and increasing the output; and the particle gradation of the slurry can be more reasonable, and the fluidity of the slurry can be improved. The overall performance of the slurry.

Dosage and method of use:

1. The commonly used range of this product is about 0.1-0.5% by weight. A series of small tests should be done before use to obtain data that can make the clay raw materials better decoagulate.

2. Add this product before ball milling. It can be dissolved in water and then mixed with the raw materials, or it can be directly added to the dry material and mixed evenly before proceeding to the pulping process.

3. After mixing and pulping, this product can make the body shape in a short time, saving at least 30% of the time compared with no additives.

4. This product can be combined with sodium oxalate and sodium carbonate.

5. This product should be sealed and stored in a dry and cool place after use.

Keyword:

More News

Ceramic Deflocculant Guide: How to Choose the Right One for Your Slip

2026-01-22

The Bio-Stability Protocol: Eliminating Bacterial Degradation in Ceramic Slurries

2026-01-16

The Non-Stick Protocol: Eliminating Demolding Adhesion in High-Volume Casting

2026-01-14

Industrial Winterization Protocol: Mitigating Deflocculant Freeze-Thaw Instability

2026-01-12

The CMC Biostability Protocol: Eliminating Bacterial Degradation in Industrial Glaze Systems

2026-01-10